-

PROTECTIVE GEOTEXTILE

This drainage liner is a geocomposite consisting of a tridimensional

polypropylene strands sandwiched between two thermomolded

filtering geotextile layers. It performs all of the following 3 functions:

drainage, separation and filtration.

-

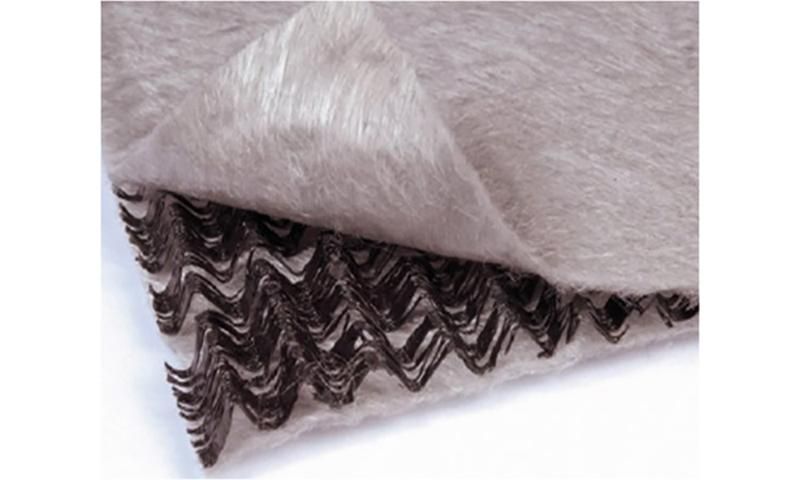

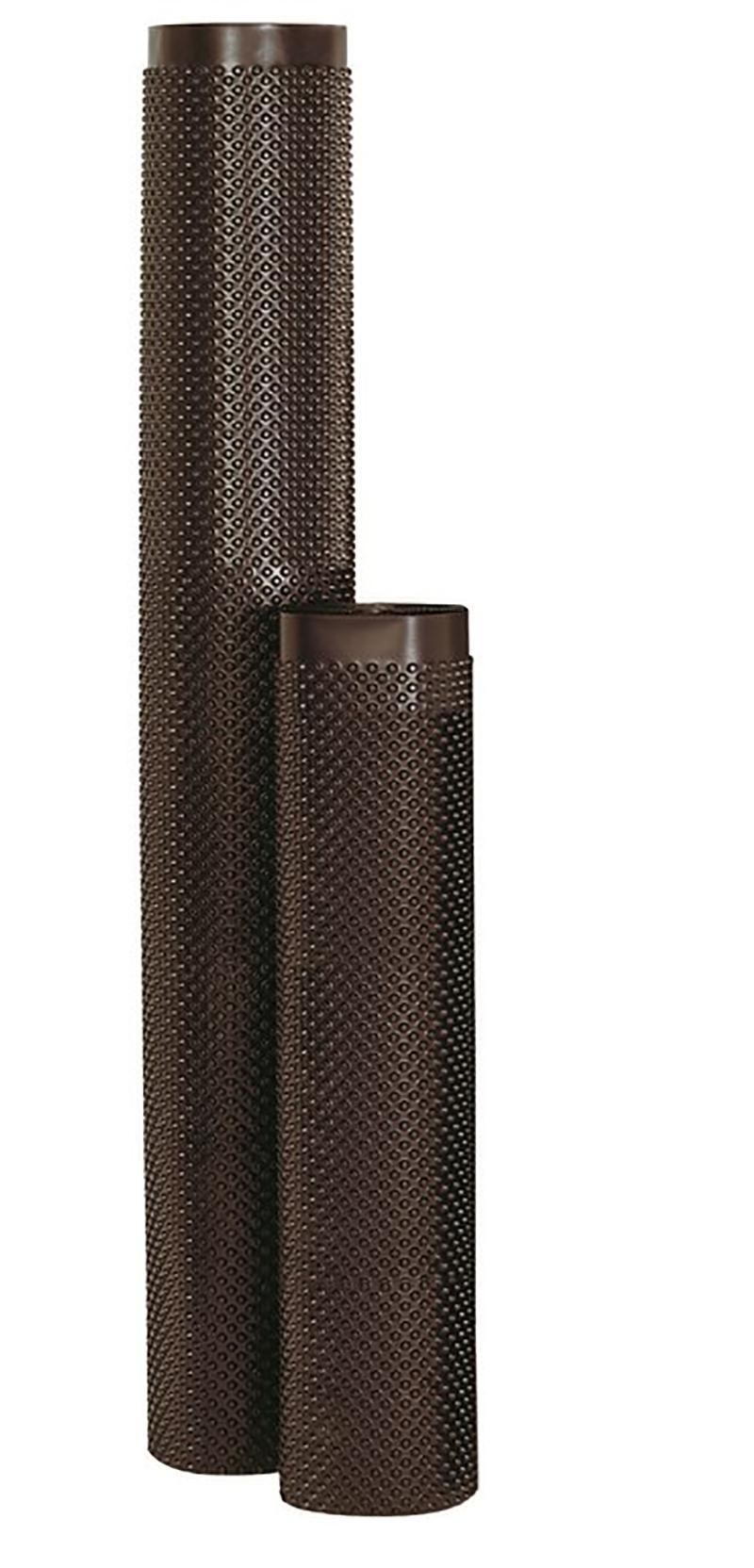

DRAINAGE LINER

This drainage liner is a geocomposite consisting of a tridimensional

polypropylene strands sandwiched between two thermomolded

filtering geotextile layers. It performs all of the following 3 functions:

drainage, separation and filtration.

It is ideally used as part of the geomembrane waterproofing system.

The drainage liner separates two materials and acts as a drain for a

fluid or gas even in a high pressure environment and/or with a low

gradient. It can replace or add to a gravel filter bed. Requires

careful installation: be careful not to crush the filter, avoid countersloping,

ensure continuity and make sure the filter is well covered.

-

ROOFING VAPOR BARRIER

This vapor-barrier film is a synthetic film manufactured by

polyethylene granule extrusion. The film is EC certified according to

standard NF EN 13984 and has been designed for use in CULTISOL

made-to-measure EPDM waterproofing installations. It avoids

condensation in the waterproofing materials, in particular in insulation

panels.

It is laid down on the flat roof substrate material (concrete, wood or

metal). It must be placed on the warm side of the insulation panel.

Double-sided adhesive is used to put in place the 10 cm cover and

finishings..

-

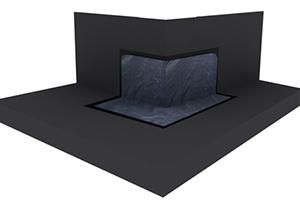

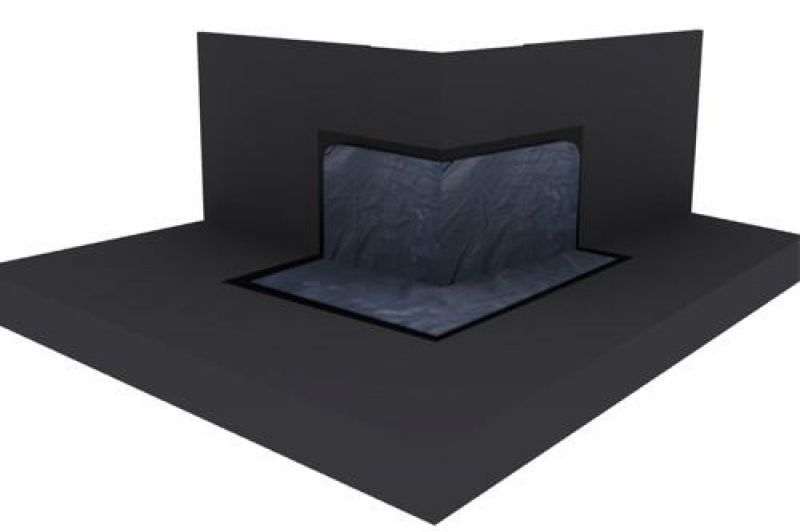

EPDM CORNER GUARDS

EPDM membrane corner guards made-to-measure by hot

vulcanization.

Used to reinforce the membrane against abrasion and rubbing.

Always used with CULTISOL made-to-measure 3D EPDM membranes

to ensure roof watertightness.

-

ALUMINIUM RAINWATER DRAIN

The rainwater drain is made of stamped, folded aluminum. It is

specially designed for use with CULTISOL customized EPDM

membranes.

Drains are set into the roof material (stone, concrete, wood, or metal)to ensure rainwater runoff from flat roofs. The crimp seal system means it can be easily and securely installed on the spot.

-

ADJUSTABLE ALUMINIUM LEAF GUARD

This adjustable leaf guard is made of aluminum wire. It is specially

designed for use with CULTISOL rainwater downpipes.

They must be positioned over each rainwater downpipe or overflow

to avoid clogging by leaves, branches and other rooftop debris.

Available in several easy-to-fit diameters.

-

GALVANIZED STEEL GRAVEL GUARD

This gravel guard is made of galvanized steel. It is specially designed

to protect rainwater downpipes against loose dirt and gravel.

They must be positioned over each rainwater downpipe to prevent

them being clogged by gravel used as ballast with CULTISOL madeto-

measure EPDM membranes.

-

EPDM RAINWATER DRAIN

The rainwater drain consists of a rigid PVC pipe (or sleeve) and an

EPDM membrane flange. The two components are assembled using

a special heat welding technique.

Supplied in standard 90, 110 and 125 mm dimensions.

Used mainly for roof waterproofing, but can also be used in other

waterproofing applications.

Cold-sealed with Cultisol EPDM on EPDM adhesive or secure

-

SHAPED ALUMINIUM FLASHING

The flashing is shaped by folding a sheet of aluminum. Specially

designed to mechanically secure CULTISOL made-to-measure EPDM

membranes.

The flashing is shaped by folding a sheet of aluminum. Specially

designed to mechanically secure FLEXIRUB made-to-measure EPDM

membranes.

-

ALUMINIUM DRIP EDGE FLASHING

Drip edge flashing is shaped by folding a sheet of aluminIum.

Specially designed to secure FLEXIRUB made-to-measure EPDM membranes at roof edges.

The drip edge flashing is used to ensure a perfect finish to sealing

upstands.

It is secured using screws or hammer fixings every 30 cm in the predrilled

-

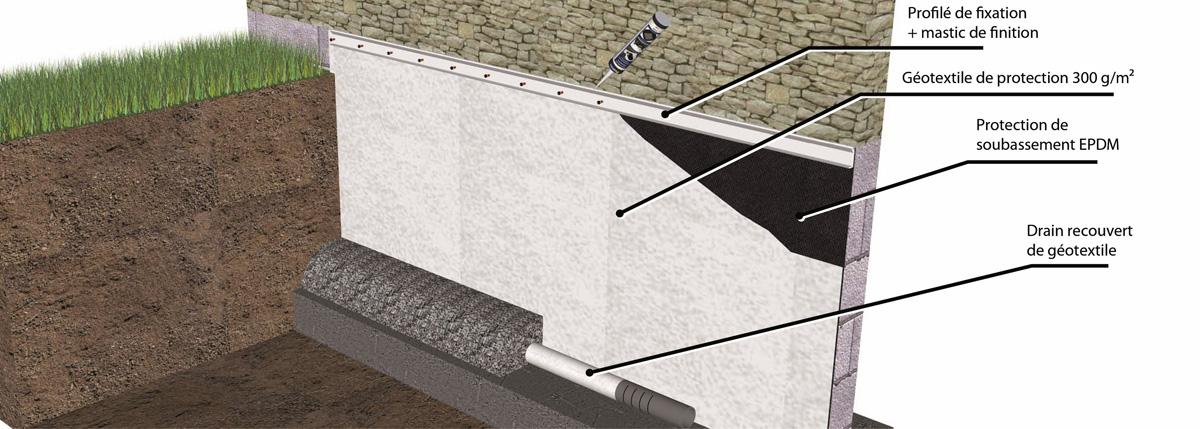

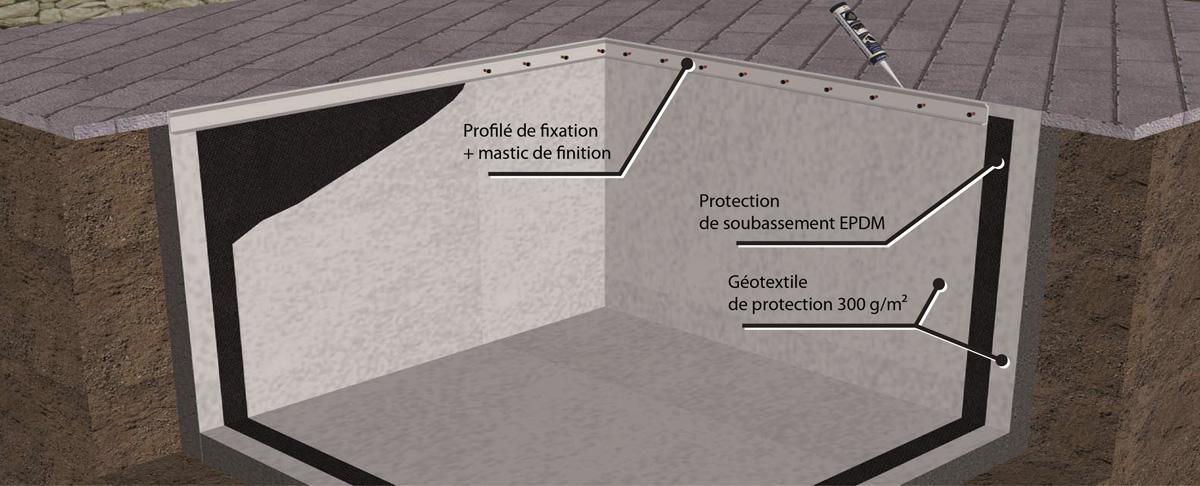

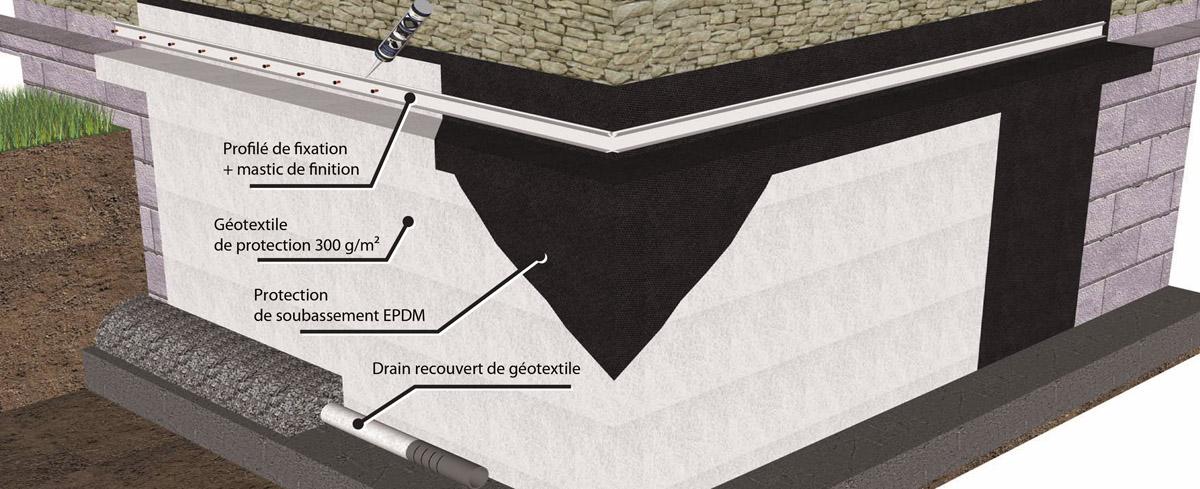

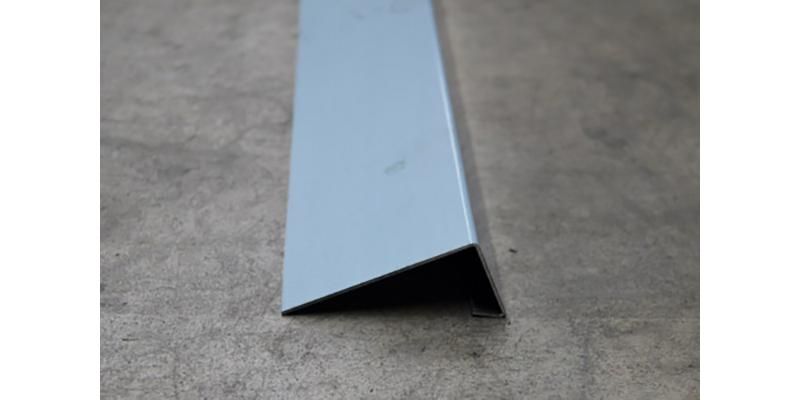

FASTENING PROFILE

The Fastening profile are used to mechanically fix EPDM finishes to the wall. They ensure the watertightness of the solution by blocking the water flowing along the wall.

Dimensions: 3,74 cm x 3,05 m (sold by 5)

-

EPDM MASTIC

Flexirub’s EPDM adhesive is a single-component MS polymer-based moisture cured adhesive. For use as a waterproofing and adhesive agent with EPDM membranes. Will secure any kind of bonding.

(Please contact Flexirub’s technical department if in doubt over compatibility with certain specific materials)

Perfect for finishes or for repairing torn or perforated membranes.

Multi-purpose adhesive designed to bond with many types of

materials: wood, concrete, metal, etc. Before applying, make sure

the EPDM surface is clean and free of oil and grease to guarantee

perfect bonding. (use only alcohol-based and not petroleum-based

cleaning agents).

Fiche De Données Sécurité Mastic EPDM

-

DOUBLE FACE ADHESIVES FOR EPDM MEMBRANE

Double-sided butyl adhesive allowing the junction between EPDM membrane and various fixing supports

- Used in addition to glues and sealants

- Ideal for securing a flexible EPDM collar or for fixing a sealing gauge

Dimensions: Width 25 mm or 50 mm or custom-made

-

GLUE FOR EPDM MEMBRANE ON WOOD AND CONCRETE SUPPORT

Adhesive based on acrylic resin allowing adhesion of the EPDM membrane on wood and concrete support

• Solvent-free and odorless glue

• Gluing by simple gluing

• Allows repositioning of the membrane

Up to 30 minutes after application

Average consumption: 0.25 liters per 1 m²

Volume: 2 L pot or 8 L bucket

Fiche De Données Sécurité Colle Membrane EPDM Sur Support Bois-Béton

-

ALL-SURFACE EPDM MEMBRANE ADHESIVE - 5 L

-

EPDM ON EPDM MEMBRANE ADHESIVE - 1 L

-

INSTALLATION TOOL KIT

Kit of installation tools allowing a perfect installation of the membrane and accessories

Composed of a pair of scissors, a marking pencil, a brush, a roller, a masking tape, a mastic cartridge and a putty gun.

-

REPAIR KIT

Kit consisting of a square EPDM membrane, a butyl glue, a mastic cartridge

And abrasive paper to allow cleaning before repairing a damaged membrane

-

SINGLE-USE LIFTING LOOP

Flexirub supplies three types of lifting loop to facilitate movement of the EPDM geomembrane rolls.

Dimensions:

- Maximum working load of 500 kg: 30 mm x 5 m

- Maximum working load of 1000 kg: 60 mm x 5 m

- Maximum working load of 1500 kg: 90 mm x 5 m

-

ANTI-ROOT BARRIER

The root barrier protects sensitive areas by deflecting roots downwards. The Isofilma root barrier consists of a non-woven, 100% polypropylene fiber geotextile, coated with polypropylene on both sides. This combination creates an extremely strong barrier that is impenetrable to roots whilst guaranteeing healthy development of trees and plantings.

Dimensions: 1.40 x 25 m

ADVANTAGES

- Exceptionally long-lasting (25 years)

- Impact resistant

- Light and easy to use

- Resistant to bacteria and chemicals

- Specific anti-UV treatment

- No risk to the environment - product is fully recyclable

-

WATERPROOF FLANGE COLLAR

The waterproof flange collar is the only 100% waterproof solution on the market.

It is composed of two distinct parts:

- A first sticker that allows to adjust its drilling, to avoid tearing and to guide the pipe during the installation.

- A second part assembled by clamping, consisting of two flanges and a joint.

-

PLINTH FOAM

The 3 mm skirting foam contributes to the acoustic and thermal insulation of floating floors and floor coverings. The Isofilma skirting foam is produced by non-polluting processes and is totally free of chlorine, emollients, halogens, sulfur, silicones and stabilizers from heavy metals.

Dimensions : 100 mm x 50 m.

ADVANTAGES

- Avoids sound bridges and tile cracks

- Heatable floor heating

- Respects the expansion of the parquet

- Two thicknesses available for different performance levels

-

PROTECTIVE COVER FOR CEMENT

Translucent cover to protect the cement from moisture.

Dimensions : 1,25 m (2 x 0,6 m) x 1,70 m.

ADVANTAGE

Allows cement storage outside

-

PROTECTIVE COVER FOR GYPSUM BOARD

Translucent cover to protect drywall against moisture.

Dimensions: 4 mx 1.8 m or 4.5 mx 1.8 m.

ADVANTAGE

Allows storage of plasterboard outside

-

SOFT CONICAL COLLAR EPDM

The flexible conical flange is the ideal solution for all connections on variable diameters. It is manufactured from a base and an EPDM sleeve manufactured in a cone with a diameter of 50mm to a diameter of 200mm. The assembly is fully assembled by hot vulcanization

-

ANCHOR ACCESSORIES

Flexirub offers different accessories to facilitate the anchoring of its membranes. They are classified into two distinct categories: eyelets and fastening rings.

Features:

- Stainless steel eyelets: Øint 9 mm or 15 mm or 25 mm

- Nickel-plated brass eyelets: Øint 40 mm

- "Half-moon" or "triangle" rings: Ø 6 mm x 50 mm

-

ALUMINUM ROOF OUTLET

The roof outlet is made of stamped, folded aluminum. It is specially

designed for use with FLEXIRUB customized EPDM membranes

Overflows are set into the roof material (stone, concrete, wood, or

metal) so as to ensure rainwater runoff in case the downpipes cannot

cope. The crimp seal system means it can be easily and securely

installed on the spot.

-

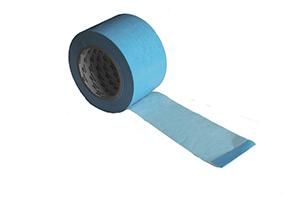

DOUBLE SIDED ADHESIVE VAPOR BARRIER ROOFING

Allows to connect the widths of vapor barrier film to each other

• Facilitates the fixation of the film on the support

Format: 60mmx20m

-

PVC FEMALE CAP

Female-threaded PVC end caps are designed to allow easy

connexion with various CULTISOL waterproofing items.

Off-the-shelf fittings have a standard diameter, but customized

diameters are available on demand.

They are used as end caps on CULTISOL EPDM bladder tanks.

Connexions must be made watertight using enough teflon (PTFE) to

eliminate any play and avoid over-tightening.

Never use oakum or other sealants used for metal plumbing joints.

-

PVC OVERFLOW WITH 90° BEND

The 90° elbow fittings are threaded at both ends to allow easy

connexion with various CULTISOL waterproofing items.

Off-the-shelf fittings have a standard diameter, but customized

diameters are available on demand.

They are used as drain outlet accessories on Flexirub EPDM bladder

tanks.

Connexions must be made watertight using enough teflon (PTFE) to

eliminate any play and avoid over-tightening.

Never use oakum or other sealants used for metal plumbing joints.

-

PVC DRAINAGE VALVE

PVC-uH valves are simple quarter turn open/shut fittings. Threaded

at both ends to allow easy connexion to other pipes.

Off-the-shelf fittings have a standard diameter, but customized

diameters are available on demand.

-

PVC THROUGH WALL CONNECTION

Allows the formation of a tight connection between the filling elements (tap, supply pipe, etc.) and the interior of the flexible tank

• Consists of a threaded spindle, two nuts and two EPDM flat seals

-

METAL FASTENING CLIPS

Permit secure attachment of ground protection geotextile

-

METAL RINGS

Stainless steel for excellent resistance to corrosion and aging

• Made by hot forging for superior mechanical strength

Format: Triangle and Half Moon

-

GEOKIT® Drained and undrained tertre

This GeoKit® contains the following components:

- 1 separation geogrid

- 1 separation geotextile 150 g / m²

- 1 LDPE film 0.4 mm (in the case of the drained mound)

- 1 watertight flange collar (in the case of the drained mound)

- 1 adhesive collar (in the case of the drained mound)

-

PVC GEOMEMBRANE 1MM

Complies with NF DTU 64.1

• Allows waterproofing of drained sand filters

-

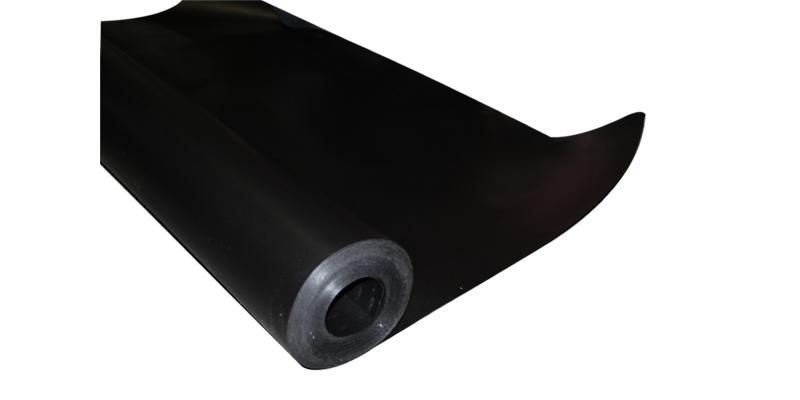

LDPE FILM 400 µm

This black 0.4 mm LDPE coextruded film offers very good mechanical

resistance properties, thanks to its triple-layer technology. Rotproof

and waterproof.

Black LDPE 400 μm film is used in self-standing wastewater treatment

systems, in particular to ensure watertightness in watertight drained

sand filter, raised bed or compact sand filter systems. It can also be

used in undrained sand filter systems, for lateral watertightness.

-

SEPARATION GEOGRID

The separation geogrid, or filtration grid, is manufactured from High-

Density Polyethylene (HDPE). The material is highly-resilient while

maintaining a degree of flexibility. For optimal efficiency, the

geogrid must be used with a separation and filtration geotextile to

retain the finest particles and avoid clogging.

The geogrid is mainyl used in waste-water treatment installations. It is

used in particular to separate different granular layers. It is

mandatory with a sand filter or other artifical soil filtration systems.

-

GEOPLUS® SPREADING

Allows separation of gravel and topsoil in trenches

-

THREE-LAYER COEXDALLE

• Prevents moisture rise by capillarities

• Complies with DTU 13.3 relating to pavements

• Complies with CE and NF EN 13967 standards

Three-layer polyethylene three-layer underpadding film

• Prevents moisture rise by capillarity

• Conforms to DTU 13.3 relating to pavements

• Complies with CE and NF EN 13967 standards

-

UNDER-PAVING FILM

Film under translucent plowing, single-layer polyethylene

• Prevents moisture rise by capillarity

• Conforms to DTU 13.3 relating to pavements

• Complies with CE and NF EN 13967 standards

Format : 3 m x 66 m - 6 m x 33 m - 3 m x 50 m - 6 m x 25 m - 6 m x 20 m

-

PROTECTIVE FILM

Protective film made of polyethylene

• Suitable for all types of work

• Easy to install

-

ANTI-TERMITE FILM

Three layer film with a thickness of 150 μm in polyethylene

• Created a physicochemical barrier against termites

• Non-washable film which prevents any diffusion of active material

• Product certified CTB-P + by the FCBA

• Guaranteed 10 years

Format : 5 m x 33 m

-

ANTI-TERMITE FILM FACE ADHESIVE

Format : 75 mm x 66 m

-

ANTI-RADON FILM DOUBLE-FACE ADHESIVE

Format : 19 mm x 20 m

-

CONNECTOR-ANTI-RADON FILM FACE ADHESIVE

Format : 50 mm x 25 m

-

MULCHING MAT

Woven polypropylene green mulch fabric

• UV-treated product

• Fastening by staple

• Permeable to water and air

-

GEOTEXTILE FOR EXTERIOR WORK

Geotextile in nonwoven needlepunched polypropylene 100 g / m²

• Stabilizes the floors before laying a pavement or a terrace

• Allows protection of drainage pipes

-

ANTI-RADON FILM

Film with a thickness of 200 μm in polyamide

• Created a genuine barrier to radon gas in construction

• Indoor / outdoor concentration ratio of 0.45% versus 68% for a conventional 200 μm polyethylene film

-

SUPERIOR ACOUSTIC FOAM

Polyethylene foam with reticulated closed cells

• Allows acoustic and thermal insulation

• Compatible with underfloor heating

-

FINISHING PROFILE

Profile for fixing the underbody protection to the wall

-

MOUNTING KNOBS WITH NAILS AND WASHERS

Nails and washers for fixing the profile to the underbody protection

-

BASEMENT PROTECTION

Polyethylene underbody protection

Protects bituminous paint Size: 1 mx 20 m - 1.5 mx 20 m - 2 mx 20 m - 2.5 mx 20 m - 3 mx 20 m